Available with Standard or Advanced license.

Control points are added to a parcel fabric for spatial reference and for use in a parcel fabric adjustment. Parcels can be joined to control points and control points can also be used as origin points when entering a parcel traverse.

Parcels can be adjusted to two or more control points in a parcel fabric adjustment. The result is parcels that are accurately georeferenced on the surface of the earth. While parcel dimensions accurately define parcel boundaries in relation to each other, control points, when used in a parcel fabric adjustment, result in accurately defined spatial locations for parcel corner points.

In the parcel fabric, control points are defined by x,y coordinates on a projected grid (a 2-D plane) and, separately, by a z-value representing height above sea-level. Control points do not represent coordinates in a three-dimensional Cartesian coordinate system that defines an actual ground position. The distance computed between two control points in the parcel fabric (using x and y only) is a grid distance. Distance attributes in the parcel fabric are considered to be ground distances. The parcel fabric adjustment uses the z coordinate values on the control points to compute coordinates on the projected grid. Thus all parcel fabric coordinates (including control) are projected coordinates on a grid (2-D plane) and are computed from record distances measured/stored as ground.

Lean more about the parcel fabric adjustment

Add control points to the parcel fabric

Control points can imported into the parcel fabric or added individually in an edit session. In an edit session, control points can be added using the Control dialog box. Click Maintain Control Points  on the Parcel Editor toolbar and click New on the Control dialog box to create a new control point.

on the Parcel Editor toolbar and click New on the Control dialog box to create a new control point.

Control points can be added as stand-alone, inactive control points or they can be linked to parcel points as active control points. Active control points can be used in a parcel fabric adjustment. To link a control point to a parcel point, use the Match Control Point  f tool on the Parcel Editor toolbar, or type the point ID of the parcel point in the PointID field on the Control dialog box.

f tool on the Parcel Editor toolbar, or type the point ID of the parcel point in the PointID field on the Control dialog box.

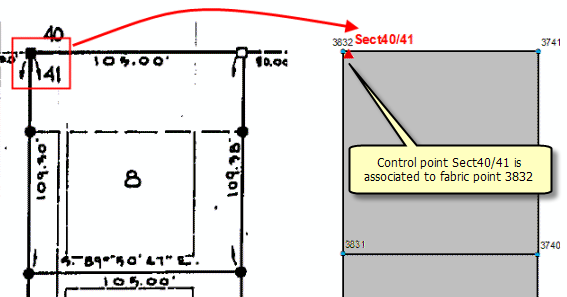

A control point can be linked to a parcel fabric point if the location of the parcel point on the ground is the same location as the control point. The mapped location of the parcel point might not match the mapped location of the control point if the control point coordinates are more accurate than the coordinates of the parcel point. Even if the parcel point does not coincide with the control point in the parcel fabric, it can still be linked to the control point.

Control points are typically located on parcel corner points or on street centerlines. When a control point does not lie on a parcel corner point , a connection line can be added from the parcel point to the control point. The control point is linked to the end point of the connection line.

Street centerlines

When a control point is located on a street centerline, you can also use an unclosed parcel to represent the street centerline and link control points to the unclosed parcel points.

To add a control point to the parcel fabric, follow these steps:

- In an edit session in ArcMap, zoom to the area where you want to add control points and click the Maintain Control Points tool

located on the Parcel Editor toolbar.

located on the Parcel Editor toolbar.

- Make sure the parcel fabricPoints sublayer is turned on in the Table Of Contents window.

- On the Control dialog box, click New and click to snap on the corresponding parcel fabric point to which the control point will be linked.

You can also type in the coordinates of the control point in the X, Y and Z attribute fields. If the control point is not linked to a point and has no associated Point ID, it will be added as an inactive control point.

- Type a name for the control point in the Name attribute field .

- If the x,y values of the parcel point do not match the coordinate values of the new control point, edit the coordinate values to match the coordinates of the control point.

- Optionally, populate the remaining attribute fields.

- Click the Update button to add the control point to the list of control points and to the map display.

If you snapped on a parcel point to create a control point, the PointID attribute field on the Control dialog box is automatically populated with the linked parcel point ID. The Name attribute field is populated with an autogenerated control point name. The X and Y attribute fields are populated with the x, y values of the parcel point. The Z attribute field is populated if the parcel point has a z value, otherwise the Z attribute field remains empty.

Link a control point to a parcel point

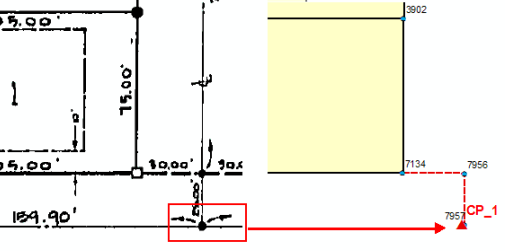

If a control point is inactive and has no associated parcel point, you can use the Match Control Point  f tool on the Parcel Editor toolbar to link the control point to a parcel point and activate it. With the Control dialog box open, snap on the control point and snap on the corresponding parcel point to link the control point to the parcel point. The PointID attribute field on the Control dialog box is updated with the linked point ID.

f tool on the Parcel Editor toolbar to link the control point to a parcel point and activate it. With the Control dialog box open, snap on the control point and snap on the corresponding parcel point to link the control point to the parcel point. The PointID attribute field on the Control dialog box is updated with the linked point ID.

Sometimes, the point ID to which a control point is linked can change. This can happen when a parcel point is merged with another point and the point ID is updated. To edit the PointID attribute, select the control point in the Control dialog box, click Edit, type a new point ID and click Update to save the edits.

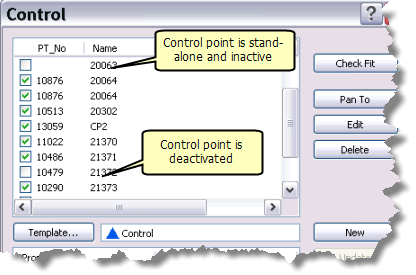

Active and inactive control points

Control points can be active or inactive in the parcel fabric. Active control points are turned on in the Control dialog box and are linked to a parcel fabric point. Inactive control points are either turned off in the Control dialog box or are not linked to a parcel fabric point.

Only active control points can be used in a parcel fabric adjustment.

Check the fit of control points

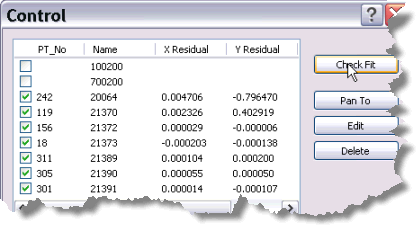

When there are more than two active control points in the map display, you can run a check fit of the control points. The check fit function checks how well the parcel network fits with the control network. Check fit is useful for evaluating how well the parcel network is going to adjust to the control network in a parcel fabric adjustment. .

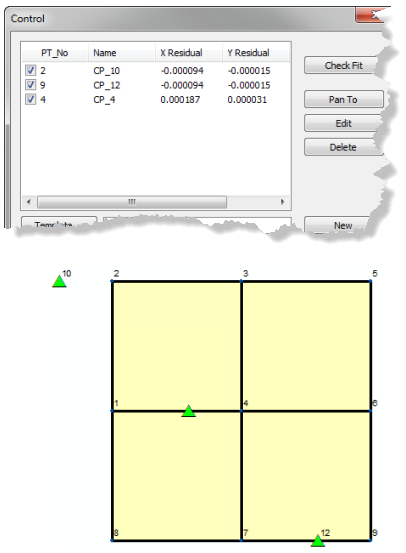

Check fit computes transformation parameters between the linked parcel point coordinates and the coordinates of the control points. The transformation used is a Helmert transformation. The computed parameters (rotation, shift in x, shift in y, and scale) are then applied to the linked parcel point coordinates to compute temporary new values for the point coordinates. The differences between the newly computed point coordinates and the control point coordinates are reported as residuals for each active control point. The residuals (dx, dy values) show how well the parcel point coordinates, when transformed to their associated control point network, fit with that network. Residuals are reported next to each control point on the Control dialog box.

Check fit residuals and the parcel fabric adjustment

It is always good practice to run a check fit on your control points before running an adjustment. The check fit residuals indicate how well the parcel network will fit with the associated control point network. Parcel lines are going to have to adjust at least by the amount of the check fit residuals in the adjustment. Therefore, check fit residuals can be used as a guideline for setting adjustment tolerances on the Adjust Coordinates dialog box. For example, the control point network may be offset by 20 feet from the parcel network, but 20-foot adjustment tolerances are not necessary for the adjustment to succeed because the parcel network transforms with minimal residuals to the control point network.

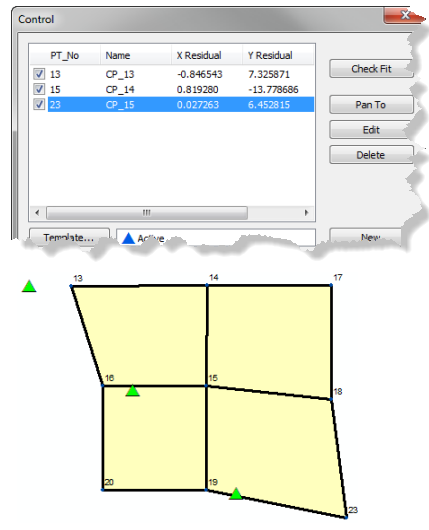

Large, inconsistent check fit residuals indicate that the parcel network does not fit well with the control network. It is not recommended that a parcel fabric adjustment be run on parcels that have large check fit residuals on their associated control points. The adjustment will most likely fail because parcel lines will need to adjust using large tolerances to fit with the control network. Adjustment tolerances should not be large for the adjustment to succeed. This will result in poor, unreliable results. The parcel network below (slightly exaggerated) does not fit well with the control network and this is confirmed by the large, inconsistent check fit residuals.

If you know that the parcel fabric has fairly good measurement precision and is devoid of errors, any erroneous or incorrectly identified control points will show large residuals when running a check fit. If you know your control point coordinates are sound, large residuals will most likely indicate a error on or surrounding the associated parcel point. If the source of the higher residual is not immediately apparent, you can choose to remove the control point from the adjustment by deactivating it in the Control dialog box. If there are errors in the parcel data, they will be identified and reported by the adjustment.

If a check fit is run after an adjustment, residuals for active control points will be zero because all the linked fabric points have been transformed into the control point coordinate system during the adjustment.