Available with Standard or Advanced license.

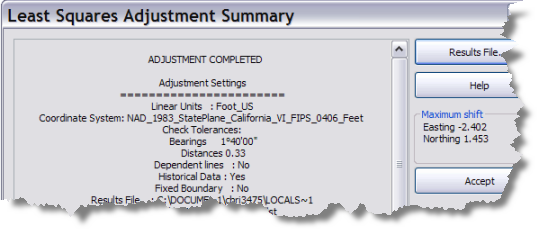

After a parcel fabric adjustment has been run on a selection of parcels, a summary of the adjustment results is displayed on the Least Squares Adjustment Summary dialog box. If the adjustment completes successfully, ADJUSTMENT COMPLETED is displayed at the top of the Least Squares Adjustment Summary dialog box.

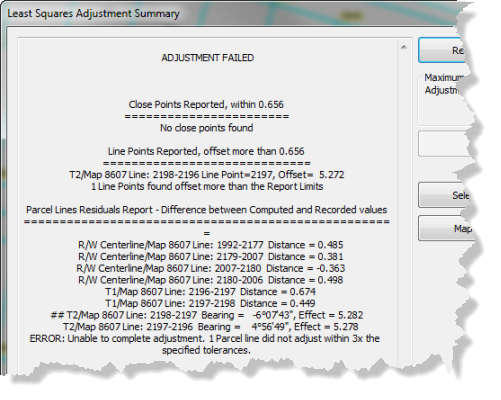

If the adjustment failed to complete, the adjustment report will state, ADJUSTMENT FAILED. Reasons for the adjustment failure are listed under the statistical reports.

Learn more about errors causing the least-squares adjustment to fail

Click Results File to view and save the adjustment summary as a text file.

Adjustment Settings

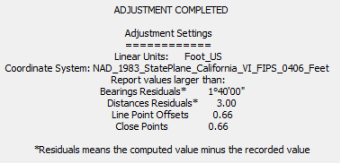

If the adjustment completes successfully, information about adjustment input parameters is listed under Adjustment Settings. These parameters include the coordinate system of the data and tolerances used for bearings and distances.

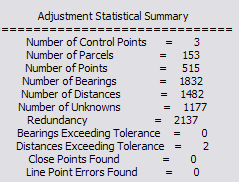

Adjustment Statistical Summary

If the adjustment completes successfully, statistical information about the adjustment is listed under Adjustment Statistical Summary. This list includes the number of control points used, the number of parcels being adjusted, coordinate residuals, and information about network redundancy.

You can also get a quick overview of the number of lines that are adjusting outside the specified tolerances as well as any close points and line points that have been found. The Parcel Lines, Close Points, and Line Points reports displayed farther down on the Least Squares Adjustment Summary dialog box lists further details about data that exceeds tolerances.

Number of unknowns and redundancy

The value listed for the number of unknowns is a measure of the actual work that is going to have to be done by the adjustment. For each point in the fabric, there are two unknowns: a correction to the x-coordinate and a correction to the y-coordinate. In addition to the corrections to fabric point coordinates, there is also a parcel rotation correction, which is also an unknown.

The bearings and distances of parcel lines are the knowns in the adjustment. An equation is generated for each bearing and each distance. If there is a line point sitting on a parcel line, two bearings are generated for that line, which is why the number of bearings is greater than the number of distances. In the example below, the number of bearings is 1,832, the number of distances is 1,482, and the number of unknowns is 1,177 for this particular adjustment.

Redundancy equals the number of bearings plus the number of distances minus the number of unknowns. For example, in the example above, redundancy equals 1,832 + 1,482 - 1,177, which is 2,137. When the redundancy is greater than the number of unknowns, the least-squares adjustment can determine the best solution as well as flag those lines that are statistically suspect. If the redundancy is the same or less than the number of unknowns, the least-squares adjustment cannot perform well and cannot determine the best solution. In the above example, the parcel network is well-conditioned, with redundancy being almost twice the number of unknowns.

Coordinate residuals

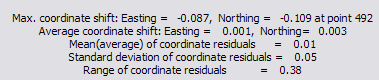

Coordinate shift statistics are also displayed under Adjustment Statistical Summary. The point that received the maximum coordinate shift is listed with the average coordinate shift for all points.

An adjustment should be run repeatedly until the maximum and average coordinate shifts become 0.0 or do not change.

Each time an adjustment is rerun, an adjustment iteration has been performed. You are iterating an adjustment if you click Run on the Adjust Coordinates dialog box or Accept on the Least Squares Adjustment Summary dialog box, then click Run again on the Adjust Coordinates dialog box to run another adjustment iteration. Once OK is clicked on the Adjust Coordinates dialog box, the adjustment is completed with no more iterations. Once the maximum and average coordinate shifts become 0.0 or do not change, the adjustment has converged to an optimal solution.

Close points reported

The close points summary lists those points that lie closer to each other than the specified tolerance and do not have dimensions (a line) between them. Close points are a good indication of points that most likely should be merged into single, common points.

Line points reported

The line points summary lists those line points that are offset from their lines at a greater distance than the specified Line points offset tolerance. Line points that are significantly offset from their adjacent parcel lines indicate data inaccuracies or incorrect parcel joining.

Line point processing

Line point processing reports how line points (and their lines) are handled during the adjustment process. This is different from how line points are handled after the adjustment process (post processing). Line point processing is reported if the Bend lines to fit line points that are offset beyond option is chosen on the Adjust Coordinates dialog box.

Line points that lie closer to their lines than the tolerance specified for bending lines are moved onto their lines and any lines that were bent to line points are straightened. Lines that lie further from their line than the tolerance specified for bending lines are bent to their line points.

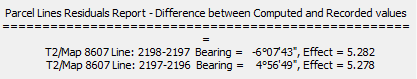

Parcel lines residuals report

This report lists all those lines that have a bearing or distance that adjusted outside the specified tolerances. The adjustment finds a best fit for all parcel points in the network and computes new coordinates for the parcel points. Parcel lines are recomputed between the new coordinates, then the recomputed line shapes are compared with the line dimensions. If a recomputed line shape differs from the line dimension by more than the specified tolerances for bearings and distances residuals, then the line is listed under the parcel lines residuals report.

Only those lines that are adjusting outside of the tolerances are listed under the Parcel lines residuals report. To see the adjustments for every line in the network, select Extended report from the Report type drop-down list on the Adjust Coordinates dialog box.

To select the parcel of a reported line, place the mouse pointer on the reported line and click Select Parcels. To zoom or pan to the selected parcel, click Map Location > Zoom To Parcels or Map Location > Pan To Parcels.

Adjustment post processing

If you checked either the force line points option or straighten road frontages option under Post Processing on the Adjust Coordinates dialog box, the least-squares adjustment summary will display a report listing the points moved. Post processing options are performed after the adjustment has completed.

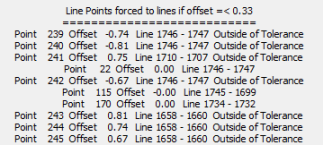

Line points forced to their lines

A list of line points that have been moved to their adjacent parcel lines is displayed under Line Points forced to their lines. The distance the line point was moved is also included in the report. If line points were found that were offset from their lines at a greater distance than the tolerance specified for Force line points onto lines if within on the Adjust Coordinates dialog box, then these line points are also listed under this report.

Straight lines report

When enforcing straight lines, the adjustment postprocessing examines a series of points, which are on adjacent parcels that are part of the same plan and are connected by lines with the same bearing. A vector for the series of points is computed, and the distance between each point in the series and the vector is measured. If the distance is less than the tolerances specified for straight lines, the point is moved onto the vector line and collinearity is enforced.

Suspect points and lines

After the adjustment, the standard deviation for all the points and lines in the network is calculated. Those points and lines with standard deviations that are greater than three times the standard deviation of the entire adjusted network are reported in the Suspect points and lines report.